HEALTH & SAFETY

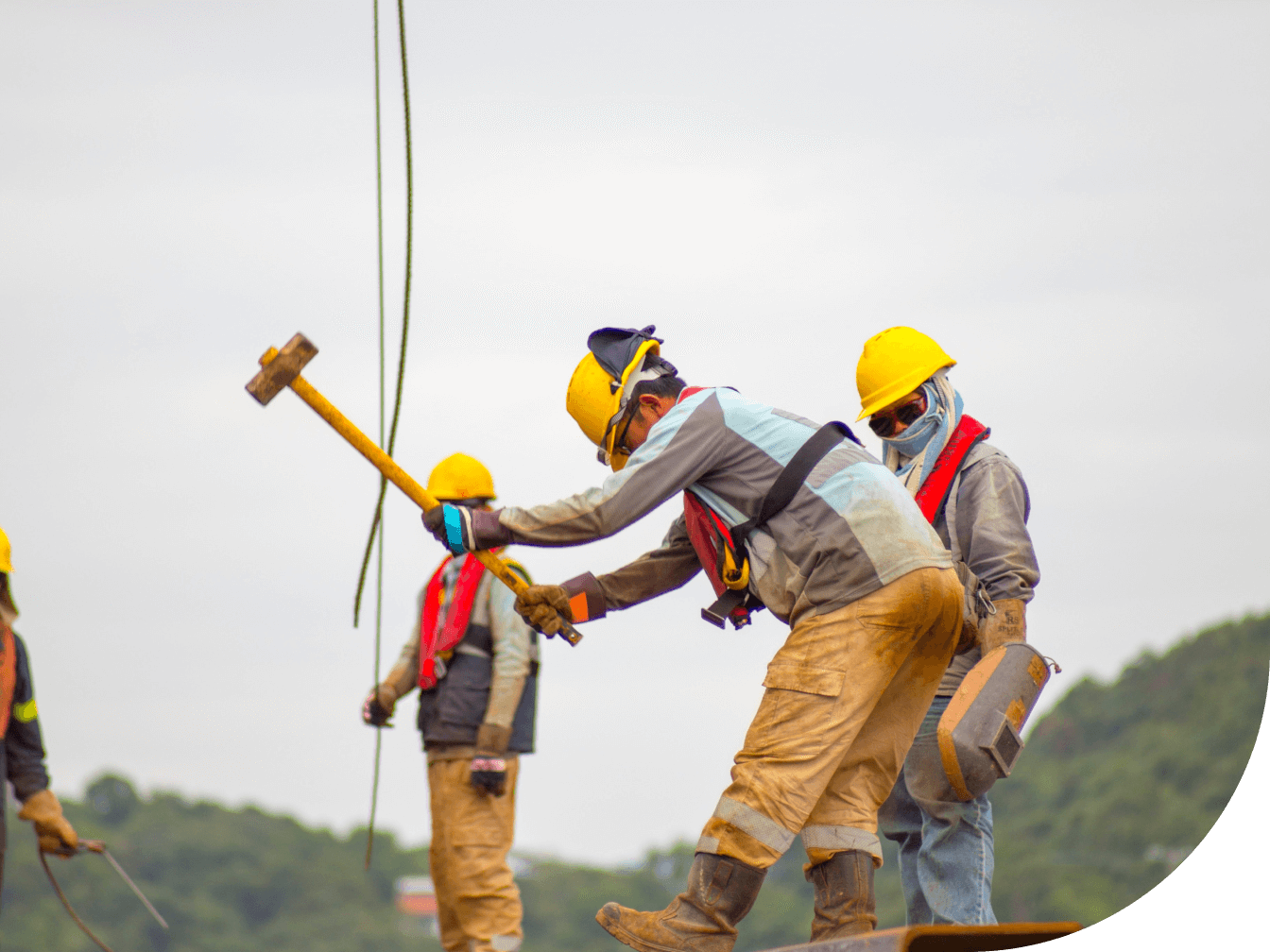

We are committed to fostering a culture of health and safety by creating a positive work environment where personal experiences are at the center of a shared journey that helps colleagues grow professionally.

Our commitment to HSE is not only focused on adopting correct methodologies and compliance with the requirements of international laws and standards but also on the awareness and involvement of all our stakeholders.

Safety and the protection of people is a core value that each of us puts into practice in all of our activities day in and day out. We strive to involve our colleagues, customers, and subcontractors in all activities because HSE is a value we all need to believe in and identify with. Through our Safethink HSE Awareness, we have defined a new approach to HSE culture by promoting initiatives with a multi-stakeholder approach. promoting initiatives aimed at strengthening awareness of these issues from a multi-stakeholder perspective.

Our HSE Policy specifies the principles, objectives, roles and responsibilities, as well as the management criteria necessary to control each HSE issue.

To best achieve these goals, we have designed and implemented a multi-site management system for Health, Safety and Environment for the Maire Group in accordance with the requirements of the ISO14001 and ISO 45001 standards, believing that a global and centralized vision is necessary to achieve excellence.

At the heart of our path is training, which is essential to ensure the development of professional skills and abilities for all group employees. This is precisely why our program includes specific courses to improve HSE knowledge, broken down by job description and role of the people involved.

As a testimony to the great work and commitment, the recognition obtained by Unindustria in 2022, which awarded our Safethink Program among the best projects in the field of HSE culture, ranking it second in the "Large Enterprises" category of the first edition of the Unindustria "Health and Safety at Work" Prize.

Over the past three years, hours dedicated to HSE and Social Accountability courses have totaled more than 4 million.

Over the past three years, aggregate hours worked at the Group's headquarters and construction sites totaled more than 165 million.

Over the past three years, Maire Tecnimont's Integrated E&C Solutions business unit's construction sites have worked more than 140 million hours. The Group's strong focus on health and safety issues is something documented by an average injury rate (LTIR) consistently below the industry average. In 2022, keeping the same benchmark data as in 2021, the LTIR indicator is about 2.5 times lower than the benchmark while the recorded TRIR is 2 times lower than the benchmark.

LTIF Five year rolling average

per Million hours

By their nature, events classifiable in the LTI category have very low frequencies of occurrence, therefore, to statistically grasp their trend over time, it is necessary to embrace a much longer observation period than a single year; to this end, the IOGP (International Association of Oil & Gas Producers), whose statistical elaborations are used by us as an industry benchmark in the HSE field, has adopted the 5-year rolling formula for the LTIR indicator, and our organization has also done similar elaboration.

Our 2023 Goals

TRIR (Total recordable injury rate)*

LTIR (Lost time injury rate)*

Training hours provided/hours worked (Construction sites)

* *on one million hours worked

SAFETHINK: OUR PROGRAM ON AWARENESS HSE

We launched a five-year plan with the aim of defining a new approach to HSE culture and raising awareness of health, safety and environmental issues among our people. The "Safethink HSE Awareness Program" consists of a series of initiatives.